Mining Locomotive

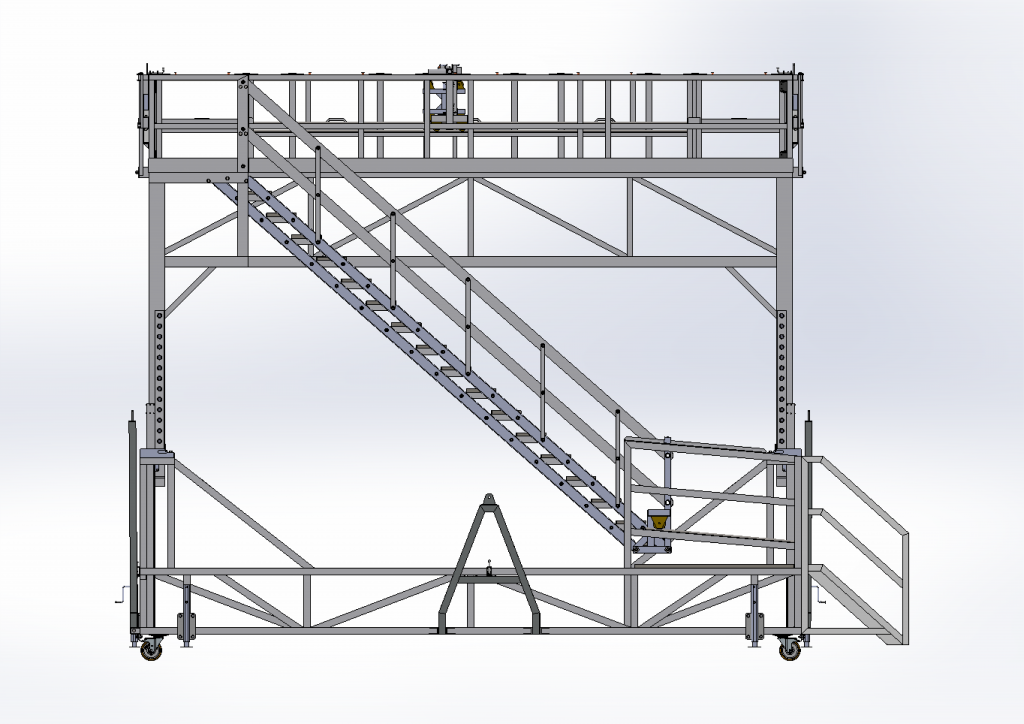

Automation & Control was approached by a major WA Mining customer who requested a solution to access the Tamper locomotive air conditioners, located on the roof top of the train, which needed to be maintained and washed.

At the time of approaching Automation & Control, the customer was installing scaffolds around the locomotives to allow access to the workers. This was both expensive and time consuming, costing up to $12,000 for each train to be maintained, with the set-up of each workstation taking about two weeks.

Project Solution

Our electrical engineers designed an adjustable platform with a reach between 3.5 to 5 meters high. Our teams were able to provide the control solution using robotic servo motors and a safety system, giving the maintenance crew safe access the Tamper Locomotives rooftop.

Project Equipment

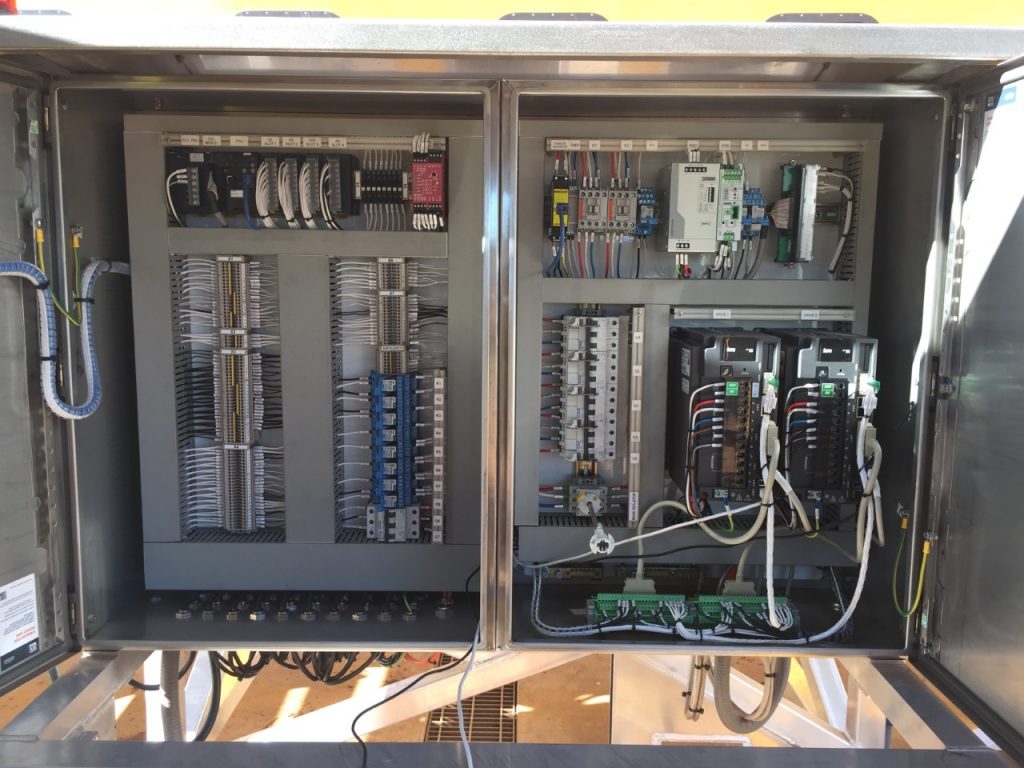

- Stainless Steel enclosure with heat panel

- 2x Delta Servo motors and drives

- 4x NOZAG Screw jack and gear boxes

- Cat II Safety system

- 2x Fortress Key Magnetic Locker

- Omron HMI and PLC

- Schneider switchgear

- IFM sensors

Project Outcomes

- Platform set-up time reduced from 4 hours to 45 minutes

- Reduction in labour costs

- ROI made in under 12 months

- Flexibility of being able to set the platform at any location in the customer’s workshop

- Expected savings of up to $864k per annum